The representatives of the IT company Plarium told us how they have realized Batman’s car, which appeared in November in front of its office, and on December 29th it will move to Gorky Park.

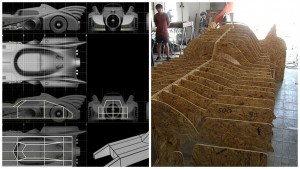

“In order to Batmobile has a strong resemblance to the original, we have created a 3D model of the car, printed patterns, and cut out the frame, which resembled a shape of the machine from the movie “Batman” by Tim Burton,” the employee of Plarium explained.

The Batmobile dimensions are closed to the original, – 6.5 x 2.5 m. It was difficult to work with such a cumbersome structure, so the guys divided it into three parts. Each frame was made of metal tubes. Thereafter, each part was filled with polyurethane foam of increased strength. They used in total 60 two-meter tubes. When all of the parts were put together, and jointed places were filled with the foam, they began resurfacing. Giving the final shape to the car body and to all the additional details took 4 months.

“The problem was the high compression ratio of the foam, – each filmed layer was worth a lot of efforts. If we removed more than it was necessary, we had to fill this area and polish it again. Then we covered the body with fiberglass. Some items were created separately and attached to the car in the process. For example, the upper part of the cabin, wheel caps and the front turbine. The patterns and shapes for them were made by hand. The wheels were attached to the frame and rotate freely, but don’t turn. As the “Batmobile” is not intended for trips, the turns implementation was inappropriate.

“The last stage was finish puttying, priming and painting. We used polyurethane black paint for the body. The resulting mixture is long erased, easy cleaning, and, in addition, resistant to chemical effect. To simulate the glass we used glossy paint. Gloss and matte body contrast creates the effect of tinted glasses”, was noted in the company.